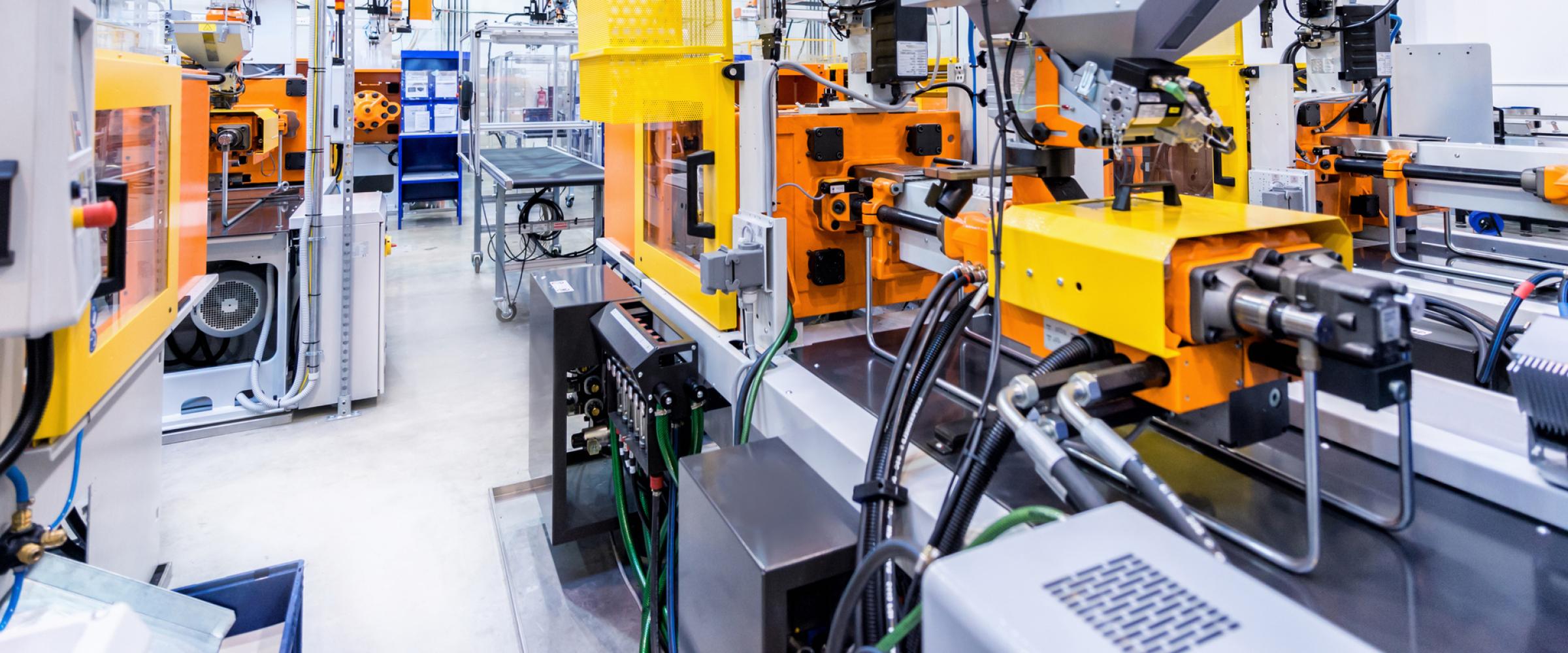

Our advanced materials, thermal science and engineering, high-performance computing, systems analysis, and technology deployment research are helping the manufacturing sector address discovery, scale-up, and device integration bottlenecks. We’re developing new polymers to enable circular supply chains, and we’re studying how to sustainably create high-volume, high-value manufacturing processes.

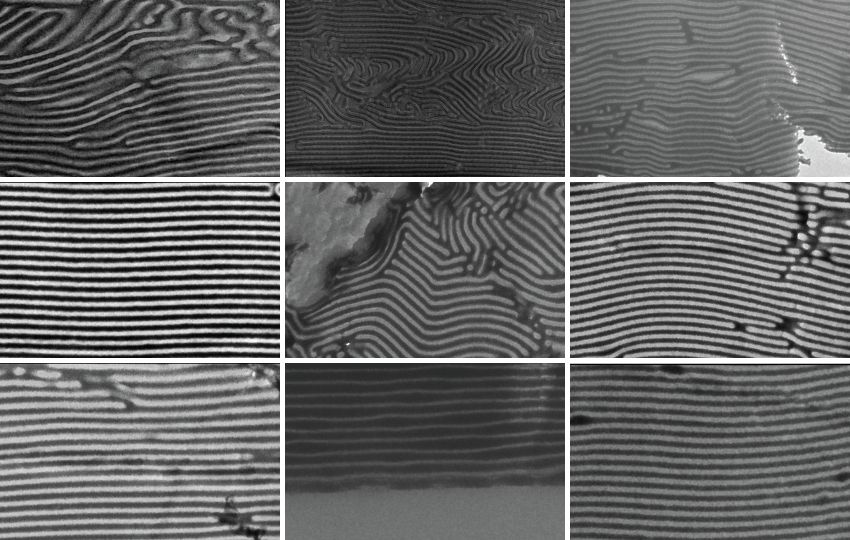

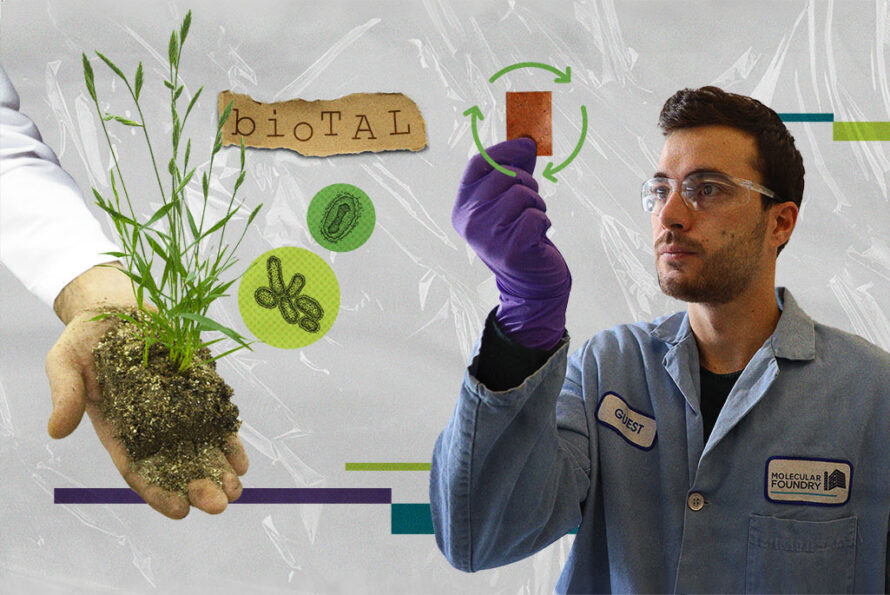

New Polymers and Systems Modeling

Discovering polymers and developing systems-level strategies in waste management and recycling to address currently unsustainable plastic waste.

Energy Management and Efficiency

Building on Berkeley Lab’s foundational energy efficiency and management research, analysis, and technical assistance to adapt best practices and technologies.

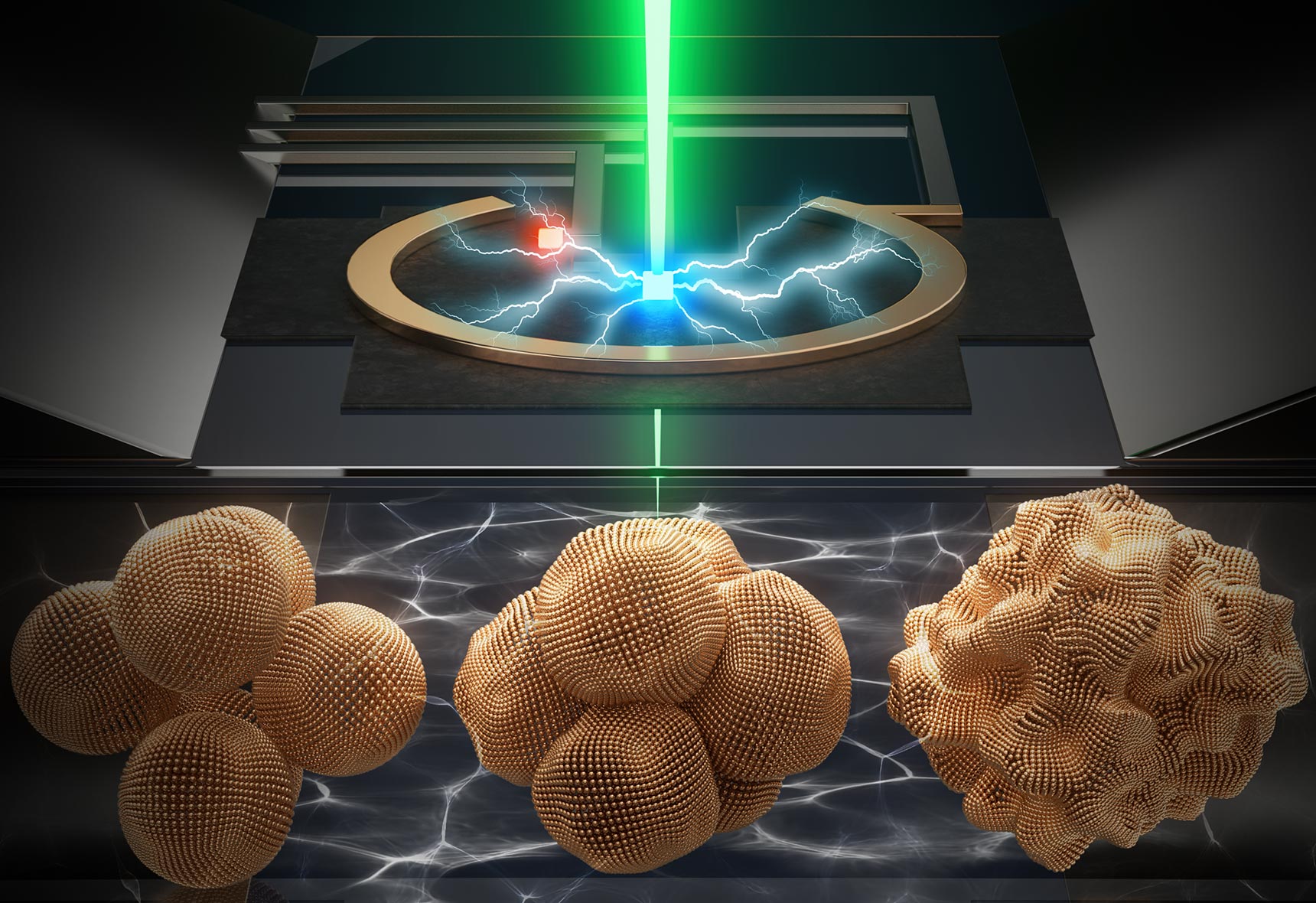

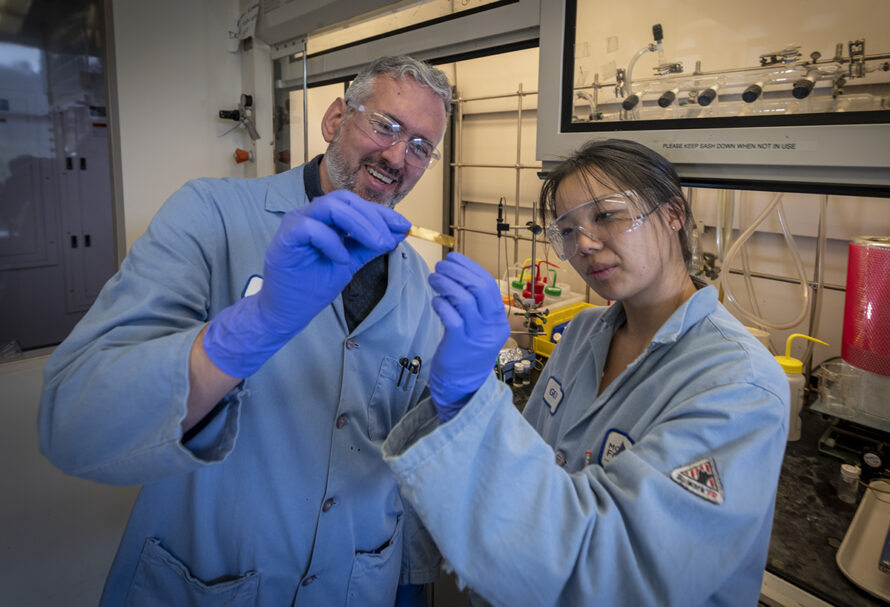

Electrochemical Refinery

Using Berkeley Lab’s materials, diagnostics, and characterization capabilities coupled with advanced computation approaches to enable more energy efficient pathways, processes, and materials for high-volume or high-value chemicals.

Industrial Heat

Studying the thermal energy required for different industrial processes to find viable alternative heat source replacements.

Developing low-carbon polymers and recycling processes compatible with waste management infrastructure.

Making energy-intensive manufacturing processes more efficient.

Assessing the energy savings potential of industrial motor systems.

Evaluating how to improve the performance, economics, and environmental impact of manufacturing innovations and other technological advancements.

Developing standards, programs, workforce qualifications, and implementation models for energy management business practices.

Developing scientific approaches to identify innovation pathways for industrial facilities.

Vi Rapp leads research on zero and low-carbon heat and power generation technologies. Her current projects include leveraging machine learning to identify bio-derived molecules to improve air quality and public health; developing novel technologies for CO2 free hydrogen production; and advancing heat and power technologies for the industrial and developing world.

Sarah Smith is a research scientist in the Energy Analysis & Environmental Impacts Division's Sustainable Energy Systems group. Her current research includes organic waste management and nutrient recovery cost and emissions modeling, end-use load shape modeling for demand response potential estimation, and battery cost, manufacturing, and supply chain analyses.

Prakash Rao heads the Buildings and Industrial Applications Department. He researches the potential for reducing the energy consumption and water use impacts of the U.S. manufacturing sector while maintaining its productivity. This work includes developing tools, resources, and roadmaps for determining decarbonization pathways for industry.

Some parts of the world have so successfully produced inexpensive renewable electricity that occasionally, there’s a surplus. One possible use for that low-cost energy is converting carbon dioxide into fuel and other products using a membrane-electrode assembly. Berkeley Lab scientists have developed a new physics modeling approach to understand this promising technology and improve the efficiency of these assembly devices.

This episode features three scientists working to manage the planet’s plastic addiction by developing smarter materials that avoid the pitfalls of 20th century plastics. We talk about the challenges of the current recycling and composting systems, philosophies of materials design, why trying to recycle some things is just “wishcycling,” why consumer preferences matter, and why we can allow ourselves to feel a little optimism — even though the news paints a pretty bleak picture sometimes.